1.Application

Hot air drying oven is applied for pharmaceutical, chemical, food, agricultural and sideline products, aquatic products, light industry, heavy industry and other materials. Such as raw materials, raw medicine, Chinese medicine Pieces, extract, powder, granules, water pills, bottles, pigments, dyes, dehydrated vegetables, dried fruit, sausage, plastic resin, electrical appliances, and baking paint, etc.

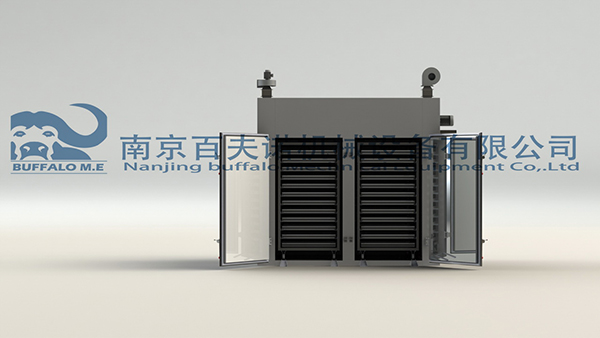

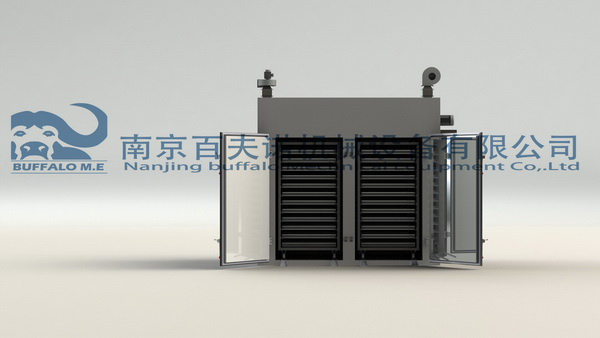

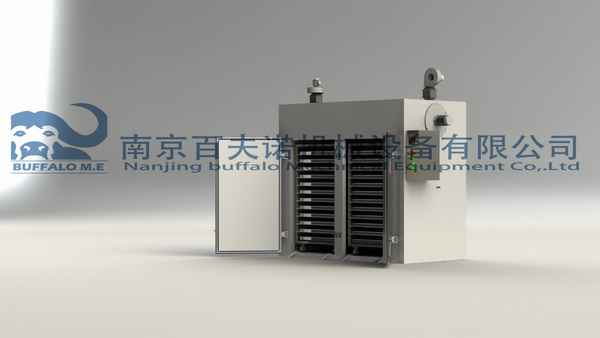

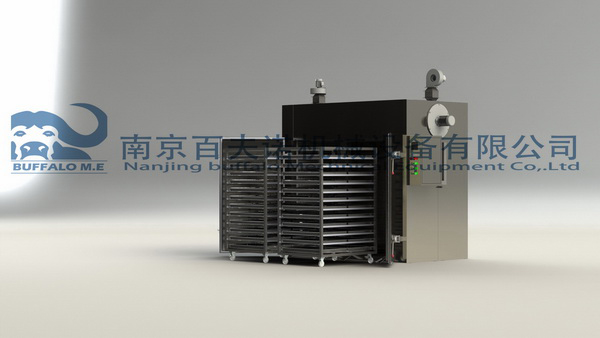

2.description

This machine is a general drying equipment; Heating method: steam, electricity, steam dual-use, for users to choose.

Working temp. : steam heating 50 ~ 140 ℃

Electrical heating temperature: 50~140℃

Commonly used steam pressure 0.02 ~ 0.08Mpa (2 ~ 8kg / cm2)

Power supply: refer to Model Ⅰ, 15Kw, accurate running: 5-8Kw/h.

special requirements can be non-standard design

Working temperature above 140℃or less than 60 ℃, to specify when ordering;

The trolley and pallet can be applied for other model equipment.

Pallet size: 460×640×45mm

3. features

Control panel with touch and button control, easy operation, long service life;

Most of the hot air circulates in the chamber, high thermal efficiency, save energy.

Forced ventilation, the chamber is equipped with adjustable air flow plate, material can be dry and uniform.

Lower noise level , temperature automatic control, easy for installation.

Widely applications, can dry a variety of materials, is a common drying equipment;

The air inlet is equipped with a high efficiency filter.

|

model |

CT-C-0 |

CT-C-Ⅰ |

CT-C-Ⅱ |

CT-C-Ⅲ |

CT-C-Ⅳ |

|

|

Drying area |

㎡ |

7.1 |

14.1 |

28.3 |

42.4 |

56.5 |

|

Useful volume |

m³ |

1.15 |

2.3 |

4.47 |

6.7 |

8.9 |

|

Production rate |

Kg/batch |

60 |

120 |

240 |

360 |

480 |

|

Steam consumption |

Kg/h |

15 |

23 |

48 |

72 |

96 |

|

Electrical heating power |

KW |

6~9 |

15 |

30 |

45 |

60 |

|

Fan volume |

m³/h |

3450 |

3450 |

6900 |

10350 |

13800 |

|

Overall size |

W(mm) |

1290 |

2270 |

2270 |

3300 |

4460 |

|

D(mm) |

1160 |

1160 |

2100 |

2100 |

2100 |

|

|

H(mm) |

1980 |

1980 |

1980 |

1980 |

1980 |

|

|

Pallet size |

W(mm) |

460 |

||||

|

D(mm) |

640 |

|||||

|

H(mm) |

45 |

|||||

|

|

|

|