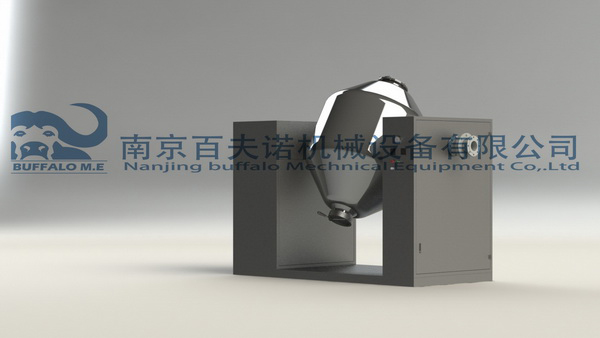

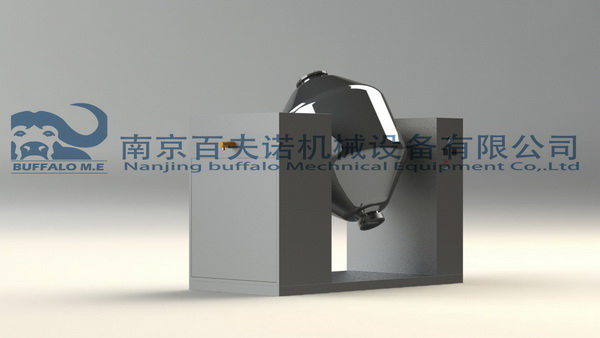

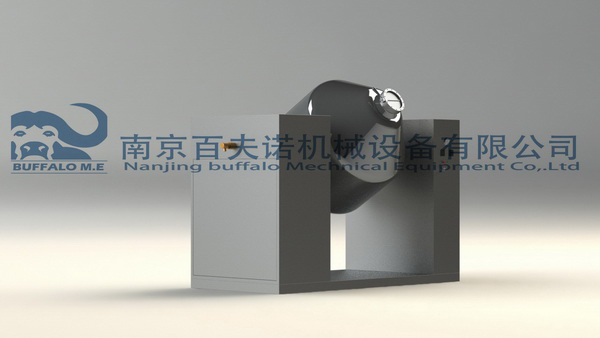

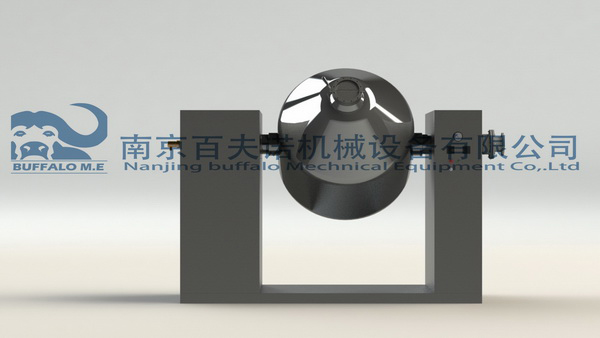

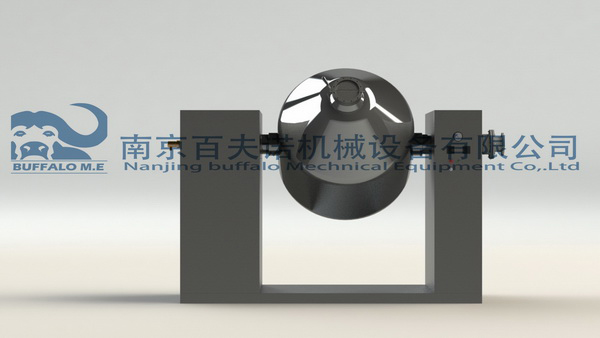

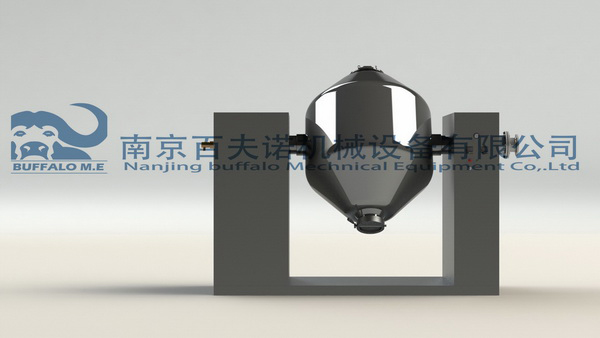

1.Vacuum Dryer Description

The dryer is developed as a new generation which conjunction with similar domestic product technology, it has belt and chain, two-level flexible connection, so as to ensure equipment running smoothly. Both ends of the shaft with a large boring machine after welding, fully guarantee the two shafts of good concentric. Both shells are made of thick stainless steel plate, so to ensure stable operation under vacuum and high pressure.

2.Vacuum Dryer Features:

A higher drying rate can be obtained at a lower temperature. Material are dried in sealed condition, no pollution during running. It has high thermal efficiency. The solvent can be recoverable. The material can be dried to very low moisture. The equipment has simple structure, easy to clean, rotating wall does not attach with material. It can not continue operation, drying speed is slow. Effective heating area is small, it is difficul for mass production.

3.Vacuum Dryer Application

It is applied for biochemical products, pharmacy, and food industry, the material can be in powder, grain, or fiber shape, etc. it is more suitable for easy oxidation, volatile, heat sensitive, strong stimulation, toxic materials and the use of chemical, It is not allowed to break the dry material of the crystal.

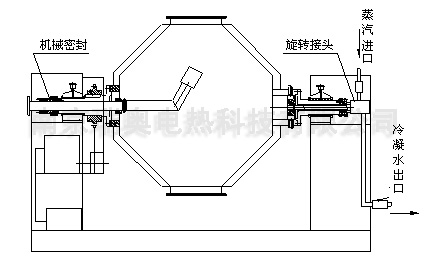

4.Vacuum Dryer working Principle :

In the sealed plate is filled with thermal energy (such as hot water, low pressure steam or conduction oil), heat through the inner shell passed to the material.

In the power-driven, the tank for the slow rotation, the contents of the tank are constantly mixed, so as to achieve the purpose of strengthening the dry.

Material in a vacuum state, the vapor pressure drop down, thus to make the surface of the material moisture (solvent) to saturation and evaporation, and timely discharge by the vacuum pump and recovery. Material within the water (solvent) continues to surface penetration, evaporation, discharge, the three processes continue, the material is dried in a very short period.

5. Main Technical Specification of Vacuum Dryer

|

Specification |

||||||||||||

|

Model |

50 |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4500 |

|

|

Overall Volume |

L |

50 |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4500 |

|

Working volume |

L |

25 |

50 |

100 |

175 |

250 |

375 |

500 |

750 |

1000 |

1500 |

2250 |

|

Heating area |

㎡ |

|

1.16 |

1.5 |

2 |

2.63 |

3.5 |

4.61 |

5.58 |

7.5 |

9.6 |

13.8 |

|

Rotating speed |

rpm |

6 |

5 |

5 |

||||||||

|

Power |

kW |

0.75 |

0.75 |

1.1 |

1.5 |

1.5 |

2.2 |

3 |

3 |

4 |

5.5 |

7.5 |

|

Rotating Rack Height |

mm |

1700 |

1810 |

1910 |

2090 |

2195 |

2500 |

2665 |

2915 |

3055 |

3330 |

4210 |

|

Total weight |

kg |

800 |

1000 |

1300 |

1500 |

1800 |

2000 |

2300 |

2500 |

3500 |

5000 |

6000 |

|

Tank pressure |

MPa |

-0.09~-0.096 |

||||||||||

|

Working temp. |

℃ |

rt+10~200 |

||||||||||

|

Sealed layer pressure |

MPa |

0.3 |

||||||||||

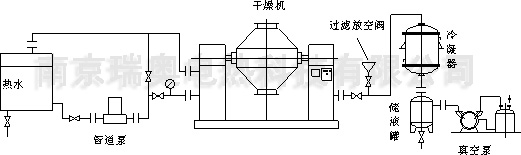

6. working process diagram:

working flow diagram

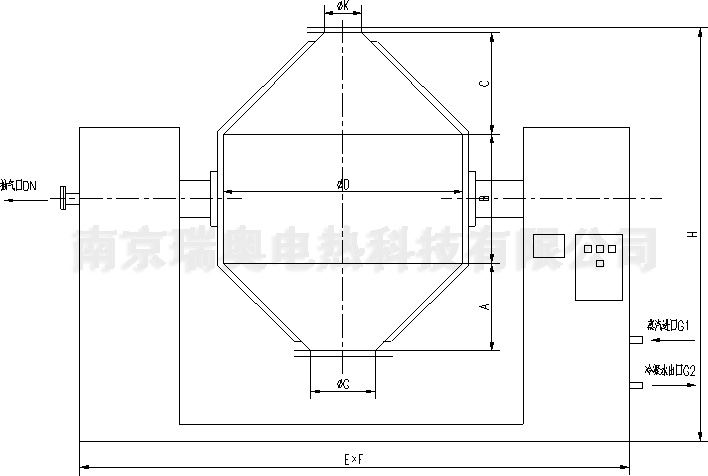

7. Installed dimension:

Main Installed Size

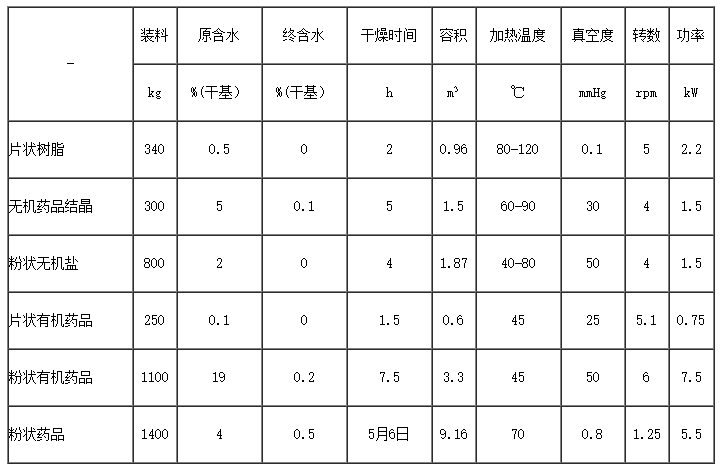

8. Vacuum dryer applied samples:

|

Specification |

||||||||||||

|

Model |

50 |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4500 |

|

|

Overall Volume |

L |

50 |

100 |

200 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3000 |

4500 |

|

Working volume |

L |

25 |

50 |

100 |

175 |

250 |

375 |

500 |

750 |

1000 |

1500 |

2250 |

|

Heating area |

㎡ |

|

1.16 |

1.5 |

2 |

2.63 |

3.5 |

4.61 |

5.58 |

7.5 |

9.6 |

13.8 |

|

Rotating speed |

rpm |

6 |

5 |

5 |

||||||||

|

Power |

kW |

0.75 |

0.75 |

1.1 |

1.5 |

1.5 |

2.2 |

3 |

3 |

4 |

5.5 |

7.5 |

|

Rotating Rack Height |

mm |

1700 |

1810 |

1910 |

2090 |

2195 |

2500 |

2665 |

2915 |

3055 |

3330 |

4210 |

|

Total weight |

kg |

800 |

1000 |

1300 |

1500 |

1800 |

2000 |

2300 |

2500 |

3500 |

5000 |

6000 |

|

Tank pressure |

MPa |

-0.09~-0.096 |

||||||||||

|

Working temp. |

℃ |

rt+10~200 |

||||||||||

|

Sealed layer pressure |

MPa |

0.3 |

||||||||||

|

|

|

|

|

|