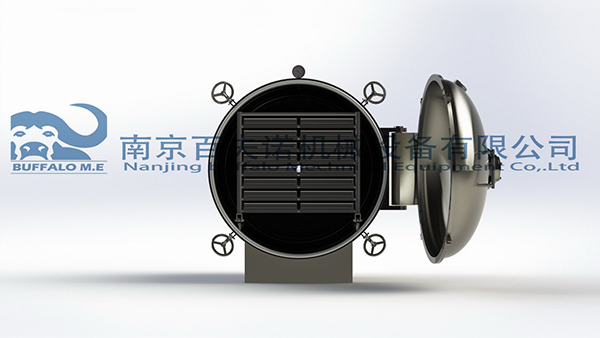

1.Vacuum Dryer Application :

It is applied to drying the materials of pharmacy, chemical, food, electronics, Chinese traditional medicine and other industries.

2.Vacuum Dryer Features:

1、Under vacuum condition, boiling point of the material solution is lower, so that the evaporator heat transfer force increases, so for certain amount of heat transfer, it can save the evaporator heat transfer area;

2、Evaporation of the heat source can be used low-pressure steam or waste heat steam; (special requirements of users choose water or oil heating, we can meet customer’s request. )

3、Heat loss of the evaporator is reduced;

4、The equipment is suitable for easy decomposition at high temperatures, polymerization and deterioration of the heat-sensitive materials drying;

5、Material can be disinfected before drying, any impurities in the drying process are not mixed;

6、The equipment is static vacuum dryer, so the dry material shape will not deformed.

|

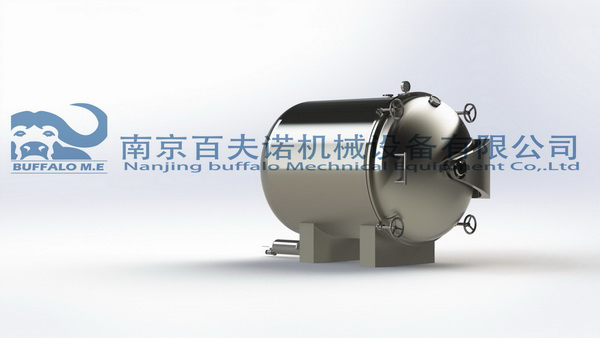

Specification |

YZG-600 |

YZG-1000 |

YZG-1400A |

|

|

Inner size |

mm |

Ø600×976 |

Ø1000×1527 |

Ø1400×2054 |

|

Overall size |

mm |

1053×745×1020 |

1590×1190×1500 |

2414×1675×1920 |

|

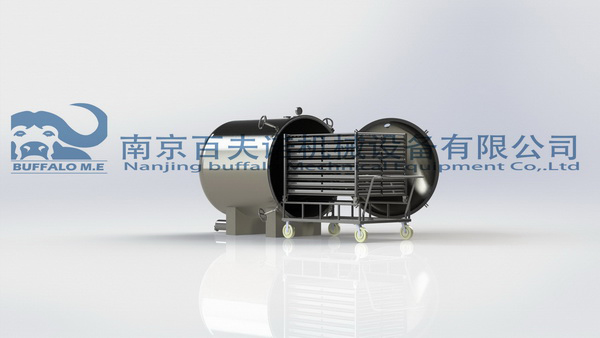

Drying layer |

piece |

4 |

6 |

8 |

|

Layers distance |

mm |

81 |

102 |

102 |

|

Pallet size |

mm |

310×600×45 |

250×410×45 |

460×640×45 |

|

Pallet number |

layer |

4 |

24 |

32 |

|

sealed tube pressure |

mpa |

≤0.784(8Kg/cm2) |

||

|

Drying rack service temp. |

℃ |

35~150 |

||

|

Vacuum degree (no load ) |

mpa |

-0.1 |

||

|

|

|

|