1.ZKE Vacuum Dryer Application:

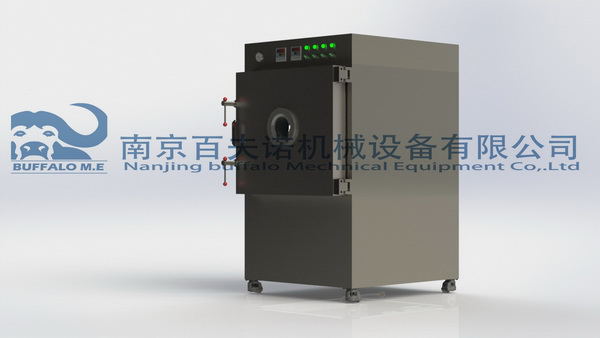

ZKS series vacuum dryer is specially designed to dry heat-sensitive, easy de-compose, and easy to oxidized material, the chamber is filled with inert gas, especially some of the complex items can also be fast drying, suitable for industrial and mining enterprises, medical schools, scientific research center.

ZKS series Vacuum Dryer Specification :

ZKS series of vacuum oven is our company’s perfect equipment with our many years of experience; after years of developing, break through the traditional technology to solve the heat transfer process in the " narrow limit condition", to find the perfect way of heat transmission.

2. ZKS vacuum dryer Features:

It forms a rectangular box, so that the effective volume to reach the maximum, it has microcomputer temperature controller, and has precise and reliable control.

Chamber can be filled with inert gas.

The door close-tightening can adjust; the overall shape of the silicone rubber door ring can ensure the high vacuum requirement.

Dryer chamber is made of stainless steel, ensure its service life. The mirror surface has good heat radiation effect.

Material is not oxidized, as storage, heating, testing and drying are free from oxygen or filled with inert gas environment.

Shortest heating time, compared with the traditional vacuum dryer, time is reduced above 50%.

Thicker wall can withstand frequent pumping, deflating, free from damage.

3. ZKS Vacuum Dryer Vacuum Degree Control:

Vacuum dryer adopts simulation of digital technology to control the degree of vacuum, "manual control" has out of time. Do you also think that today's hand-operated valves in the 21st century can precisely control the vacuum? Through the solenoid valve automatic digital control of the degree of vacuum, to provide more accurate and effective vacuum control, but also provide more up-to-date information and more convenient.

Through the panel, the vacuum from 20Pa to 9999Pa adjustable, adjustable precision is 1Pa.. The panel shows the vacuum range of work from 1Pa to 9999Pa. The vacuum sensor is located at a different location from the inlet and outlet , ensuring a stable pressure value, free of airflow, and delivering the most stable pressure value to the operator panel.

4. ZKS vacuum dryer components:

resistance vacuum gauge

intelligent program LCD temperature controller

inert gas interface

Hot water tank

Explosion-proof structure

|

model |

ZKS-80A |

ZKS-160A |

ZKS-140 |

ZKS-200 |

ZKS-380 |

||

|

Chamber |

W |

(MM) |

500 |

500 |

650 |

650 |

650 |

|

D |

(MM) |

450 |

450 |

680 |

680 |

680 |

|

|

H |

(MM) |

340 |

700 |

340 |

460 |

850 |

|

|

overall size |

W |

(MM) |

1000 |

1000 |

1150 |

1150 |

1150 |

|

D |

(MM) |

750 |

750 |

980 |

980 |

980 |

|

|

H |

(MM) |

1100 |

1500 |

1100 |

1220 |

1650 |

|

|

Volume |

m³ |

0.077 |

0.158 |

0.151 |

0.204 |

0.376 |

|

|

Pallet number |

只 |

2 |

5 |

2 |

3 |

6 |

|

|

Layers |

层 |

2 |

5 |

2 |

3 |

6 |

|

|

Pallet size |

(MM) |

400*300*40 |

640*460*45 |

||||

|

Steam area |

㎡ |

0.24 |

0.72 |

0.6 |

0.9 |

1.8 |

|

|

Energy |

蒸汽、热水 |

||||||

|

Steam pressure |

kgf/cm2 |

0.784 |

|||||

|

Working temp. |

Hot air |

℃ |

RT+10~90 |

||||

|

Steam |

RT+10~130 |

||||||

|

Limit vacuum |

mpa |

-0.1 |

|||||

|

Vacuum pump data |

2XZ-4 |

2XZ-4 |

2XZ-4 |

2XZ-4 |

2X-8A |

||

|

Pump power |

(Kw) |

0.55 |

0.55 |

0.55 |

0.55 |

1.1 |

|

|

Total installed capacity |

(Kw) |

1 |

1 |

1 |

1 |

1.7 |

|

|

|

|

|